Tandoor Manufacturer in Rajasthan

Rajasthan is not just known for its palaces, deserts, and vibrant culture — it is also deeply tied to the culinary traditions that employ clay ovens and tandoors. The tandoor has roots in Rajasthan’s ancient cooking techniques. In fact, archaeological evidence from sites such as Kalibangan in Rajasthan shows early clay ovens similar to modern tandoors being used.

Over centuries, Rajasthani kitchens and temples have used variants of clay ovens such as “bhatthi” or “sigdi,” handing down the skill of building ovens that give breads and meats a smoky, charred flavor. In that historic continuum, DurgadasTandoorWala stands today as a modern manufacturer combining tradition, technology, and quality in the heart of Rajasthan’s artisanal legacy.

Why Rajasthan Is an Ideal Hub for Tandoor Manufacturing

Rich Clay and Raw Materials

Rajasthan has abundant clay reserves, ideal for refractory and insulating applications. The availability of suitable clay, firebricks, and insulating materials means manufacturers here can source critical materials locally, reducing lead times and costs.

Skilled Craftsmanship Tradition

Artisans in Rajasthan have generations of experience in pottery, kiln design, and metalwork. This artisan tradition enables a tandoor manufacturer to blend handcraft and mechanization, giving each unit strong structural integrity and aesthetic appeal.

Strategic Location & Market Access

Being in Rajasthan places DurgadasTandoorWala in relatively central access to Northern and Western Indian markets. Logistics to states like Uttar Pradesh, Madhya Pradesh, Delhi, Haryana, Gujarat, and Punjab are more efficient than from farther corners of India.

Demand from Hospitality and Rural Markets

Rajasthan itself is a major tourism destination. Hotels, resorts, and dhabas in the state require quality tandoors. Also, due to continued use of traditional ovens in rural and semi-urban areas, demand persists in domestic and institutional segments.

Thus, as a tandoor manufacturer in Rajasthan, you benefit from proximity to raw materials, skilled labor, and a receptive regional market.

What Makes DurgadasTandoorWala Stand Out

Every manufacturer claims quality, but your brand must deliver distinct advantages. Here are ways DurgadasTandoorWala can be positioned:

Fusion of Tradition and Innovation

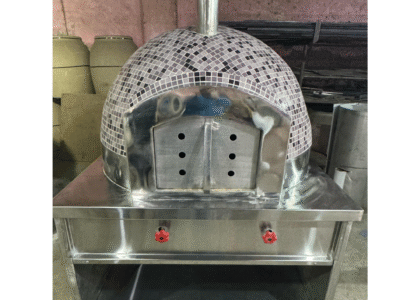

While staying true to clay-based heat retention, DurgadasTandoorWala integrates modern features: double-wall insulation, refractory liners, stainless steel exteriors, temperature gauges, and modular designs.

Tailored Customization

Unlike fixed-design vendors, DurgadasTandoorWala offers customization in:

Size (height, diameter, footprint)

Fuel type (wood/coal/charcoal, LPG, gas, electric)

Exterior finish (brick façade, tiles, metal cladding)

Additional attachments (rotisserie, skewers, chimney, doors)

Because of this, clients with unique space or menu constraints can get exactly what they need from your workshop.

Strict Quality Assurance & Testing

Every tandoor is tested for thermal stability, insulation efficiency, and safety before delivery. Defects are detected and corrected before shipment. This ensures clients receive units that perform reliably under heavy use.

After-sales Support and Maintenance

Many manufacturers ignore after-sales. At DurgadasTandoorWala, you can provide replacement refractory parts, service contracts, training on operation, and remote support to clients. That builds trust and repeat business.

Competitive Pricing with Value

Because your raw material sourcing, in-house fabrication, and location reduce costs, you can price competitively. Yet, value is preserved by premium materials and craftsmanship — a key selling point.

You will want to weave these differentiators throughout all marketing materials, proposals, and your website.

Types of Tandoors & Material Considerations

To appeal to diverse clients (restaurants, hotels, homes, etc.), DurgadasTandoorWala should offer a portfolio. Below are common types and material choices:

Major Types of Tandoors

Clay/Traditional Tandoor

A pure clay or terracotta inner pot encased in insulation and outer shell. Ideal for authentic flavor and high heat retention.Gas / LPG / Propane Tandoor

Gas burners replace or supplement charcoal to allow easier operation, adjustable heat control, and cleaner fuel.Electric Tandoor

Heating coils or elements drive the heat. Easier for indoor use where open flame is restricted.Stainless Steel / Metal Drum Tandoor

Using steel outer walls, often double-walled with insulation, with clay or refractory liner inside. Durable and easier to maintain.Portable / Mini / Tabletop Tandoor

Smaller models for home, small restaurants, street vendors. Compact but well-insulated.Barbecue & Grill Hybrid Tandoors

Units designed for skewers, kebabs, and grills along with bread baking.

Material & Engineering Considerations

Refractory Clay / Fire Bricks: The inner surface is often lined with refractory clay that can endure high temperatures without cracking.

Insulation Layers: Between inner liner and outer shell, insulation (e.g. ceramic wool, vermiculite mix) helps minimize heat loss and enhance fuel efficiency.

Outer Shell / Shell Material: Mild steel, stainless steel, or brick cladding ensure durability and aesthetics.

Fasteners & Joints: High-temperature resistant metal hardware and expansion joints prevent cracking during heating cycles.

Chimney / Ventilation: Proper smoke exhaust ensures clean combustion and user safety.

Seals & Doors: Metal doors or lids with gaskets can help seal heat, while ports for skewers or ventilation should be optimized.

By carefully selecting and engineering these components, DurgadasTandoorWala can deliver efficient, long-lasting tandoors suited to varied demands.

Design, Customization & Technical Expertise

Site Study & Requirements Gathering

For commercial clients, you should perform a site survey: measure available space, ventilation, fuel supply, load, foot traffic, workflow, and menu type. This ensures the tandoor is optimized for that environment, which minimizes revisions or onsite modifications.

CAD & Prototype Design

Use CAD software to model the tandoor: shape, air flow, insulation thickness, burner placement. Create prototypes when needed. This step lets you simulate heat distribution, structural integrity, and serviceability.

Modular & Scalable Design

Design tandoors in modular segments (inner pot, insulation layer, outer shell) to ease transport and onsite assembly. Also, scalability helps clients upgrade (e.g. add extra burners or extensions) later.

Heat Management & Airflow

A key technical skill is optimizing air intake, flue drafts, and burner arrangement so heat is uniform from bottom to top. This ensures even cooking, reduces hotspots, and improves efficiency.

Safety & Standards

Integrate safety features: heat shields, handles, door locks, proper chimney height and clearances. If possible, comply with regional safety or food equipment standards, which clients (hotels, franchises) may demand.

Testing & Iteration

Each design should be tested: bring it to full operational temperature, monitor thermal gradients, check for structural stability (expansion, cracks), and run endurance cycles. Iterative improvements refine the final design.

Because DurgadasTandoorWala focuses on both artistry and engineering, clients receive tandoors that are beautiful, dependable, and safe.

Challenges, Risks & Future Trends

Challenges & Mitigation

Material Cracks / Thermal Stress: If clay liner cracks under cycles. Mitigate via proper mix, gradual heating, expansion joints.

Transportation & Damage: Tandoors are heavy and fragile. Use modular design and protective packaging.

Competition & Price Pressure: Many vendors in Rajasthan and beyond. Emphasize quality, support, customization to avoid competing only on price.

Fuel / Emission Regulations: Switching to “clean fuel” may be mandated in some areas. Prioritize gas / electric variants.

After-sales Neglect: If clients cannot get spare parts, reputation suffers.

Future Trends

Hybrid Fuel Tandoors: Units that can switch between charcoal, gas, electric.

Smart / IoT Integration: Temperature sensors, remote monitoring, automatic fuel control.

Eco-friendly Designs: Better insulation to reduce fuel use, recyclable materials.

Prefabricated Modular Kits: Easier for remote assembly, DIY installations.

Export Markets: Overseas demand for authentic Indian cuisine can open export scope.

If DurgadasTandoorWala stays ahead by innovating, your brand can evolve from a local manufacturer to a national or even international supplier.

Conclusion

In summary, Rajasthan provides a fertile ground for tandoor manufacturing — with clay deposits, skilled artisans, and proximity to major Northern markets. DurgadasTandoorWala can carve a strong niche by fusing traditional craftsmanship with technical innovation, offering customization, stringent quality control, and strong after-sales support.

If you invest in smart design, modular construction, efficient insulation, safety features, and customer-centric services, DurgadasTandoorWala will not just be “another tandoor maker in Rajasthan” — it will be the trusted name in Indian tandoors.