Tandoor Manufacturer in Hyderabad

In the heart of Hyderabad, where culinary traditions meet innovation, Durgadasstandoorwala stands as a premier manufacturer of tandoors. Hyderabad’s food culture is rich, and restaurants, caterers, and food startups constantly look for reliable, efficient, and durable tandoor ovens. This blog explores why Durgadasstandoorwala is trusted, what sets a great tandoor manufacturer apart, and how to choose the right tandoor for your needs.

Why Hyderabad is a Strategic Hub for Tandoor Manufacturing

1. Culinary Demand and Food Culture

Hyderabad is known for its biryanis, kebabs, and rich north-Indian and Mughlai cuisine. Restaurants across the city require high-performance tandoor ovens to maintain consistency in taste and volume. Because of that demand, tandoor manufacturing has found fertile ground here.

2. Industrial Infrastructure

Hyderabad houses robust manufacturing clusters including in areas like Sanathnagar and Azamabad Industrial Estate. These zones provide access to metalwork, welding, and fabrication resources. Wikipedia+1 Moreover, suppliers of stainless steel, refractory materials, and equipment are locally available.

3. Proximity to Markets Across South India

A manufacturer based in Hyderabad can serve markets in Telangana, Andhra Pradesh, Karnataka, Tamil Nadu, and beyond with relative ease. Logistics costs and lead time advantages help firms like Durgadasstandoorwala compete effectively.

About Durgadasstandoorwala

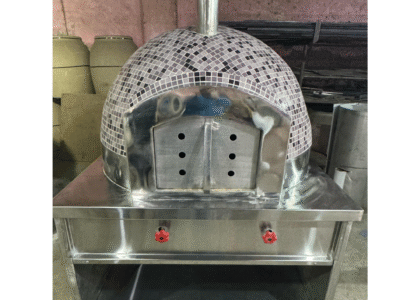

At Durgadasstandoorwala, we specialize in designing and manufacturing clay, gas, charcoal, and hybrid tandoor ovens tailored for commercial kitchens, restaurants, caterers, hotels, and food trucks. Our mission is to combine tradition with technology and deliver ovens that maximize efficiency, durability, and cooking quality.

Our Product Range

Clay / Terracotta Tandoors: Embedding traditional heat retention.

Gas / LPG / NG Tandoors: For easier control and cleaner operation.

Charcoal / Wood-fired Tandoors: For authentic smoky flavor.

Hybrid Models: Combining gas start with charcoal backup.

Accessories: Grills, racks, thermal insulation linings, refractory bricks.

Key Differentiators

Customization — Shapes, sizes, capacity, and fuel type are customized to clients’ needs.

Material Quality — We use high-grade refractory clay, insulation layers, and stainless steel casings where needed.

After-sales Support — Installation, maintenance, spare parts and service are provided.

Quality Assurance — Each tandoor is tested for heat retention, thermal shock resistance, and durability before dispatch.

By keeping these attributes at the core, Durgadasstandoorwala has garnered trust among restaurateurs in Hyderabad and nearby regions.

What Makes a Great Tandoor Manufacturer?

When evaluating manufacturers in Hyderabad (or elsewhere), keep the following criteria in mind.

1. Material and Construction Quality

Refractory core or terracotta must be crack-resistant, pure, and of consistent density.

Insulation: Proper insulating materials reduce heat loss and fuel consumption.

Outer structure: Stainless steel, mild steel, or masonry casings should resist corrosion and deformation.

Welds, joints, sealing: Poor workmanship invites leaks and inefficiency.

2. Thermal Performance

Heat retention: Ability to maintain high internal temperature for extended cooking.

Even heat distribution: No cold spots.

Fuel efficiency: Less gas, wood, or charcoal needed per unit of cooking output.

3. Versatility & Design

Ability to cook breads (naan, roti), kebabs, tikkas, meats, vegetables.

Provision of racks, hooks, grills, skewers.

Modularity or ease of maintenance.

4. Compliance & Safety

Gas safety valves, flame arrestors, insulation safety.

Certifications if required (local, industry, safety norms).

Ventilation and exhaust design.

5. After-sales Service & Spare Parts

Readily available spare refractory liners, burners, fittings.

Technician support and repair services.

Warranty and guarantees.

6. Local Support & Proximity

Being local (Hyderabad) helps reduce lead times and costs.

Easier site visits, installation supervision, and servicing.

Among manufacturers in Hyderabad, many specialize in stainless steel tandoor bhattis or gas tandoors. Some firms advertise methane and charcoal models. But not all offer full customization or service support like Durgadasstandoorwala.

Challenges Faced by Tandoor Manufacturers

No business is without challenges. In Hyderabad, tandoor manufacturers often face:

1. Material Quality Variation

Some refractory clays or insulation materials may have impurities or inconsistency, causing cracking or heat leaks.

2. Thermal Stress and Cracks

Frequent heating and cooling cycles can cause thermal shock. Designs must allow for expansion joints or controlled cooling.

3. Fuel Efficiency Pressure

Customers expect lower gas/charcoal consumption. Achieving that requires engineering innovation.

4. After-sales & Maintenance

Clients may not maintain ovens properly, leading to damage. Warranty and service obligations need strong backup.

5. Competition

In Hyderabad there are many stainless steel tandoor bhatti manufacturers, gas tandoor makers. seacool.net+2ExportersIndia+2 To stand out, Durgadasstandoorwala must emphasize quality and service.

6. Installation & Ventilation

On-site installation, ducting, chimney, exhaust and safety must be handled properly; poor installation reduces performance.

7. Compliance & Safety Regulations

Meeting local safety, emission, gas codes, and fire regulations is needed in commercial kitchens.

Despite these challenges, with proper design, testing, and customer education, they can be addressed.

Process of Manufacturing at Durgadasstandoorwala

Here’s a simplified overview of how we at Durgadasstandoorwala design and manufacture tandoors:

Requirement Gathering & Design

Meet client, collect load, size, fuel preference, site constraints. Prepare drawings and thermal simulation.Material Selection

Procure refractory liner/clay, insulation (ceramic fiber, vermiculite, etc.), outer shell steel, burners, hardware.Core Construction

Build inner clay core or refractory shell, form shape (cylindrical, barrel, square). Fire or cure.Insulation Layer

Surround core with insulation to minimize heat loss.Outer Casing & Structure

Fabricate the outer shell using stainless steel, mild steel, sheet metal or masonry. Include doors, access panels.Fuel System Integration

Install gas burners, inlet piping, valves, burner holders, igniters. Or set up charcoal/wood ports and vents.Accessories & Racks

Provide skewer hooks, grill racks, drip trays, exhaust flues, chimney attachments.Testing & Calibration

Heat the tandoor, measure internal temperature, check for leaks, structural stability, fuel consumption.Final Finishing & Packaging

Paint or polish exterior, package carefully, attach manuals, spare parts, etc.Delivery & Installation

Ship to client site. Our technicians install, test on site, and provide training.

This full control over process enables quality assurance and better customer satisfaction.

Conclusion

In Hyderabad’s vibrant food ecosystem, a tandoor manufacturer must blend tradition, engineering, and service. Durgadasstandoorwala is committed to delivering that blend — from custom design and quality materials to on-site installation and after-sales support.

If you are seeking a reliable tandoor manufacturer in Hyderabad for your restaurant, catering unit, or food venture, consider Durgadasstandoorwala as your trusted partner.

We welcome inquiries, site visits, and consultations. Let us help you bring excellence to your tandoor cooking solutions.